Machine safety and control equipment

Machine Safety & Functional Safety Tests

Machine Safety & Functional Safety Tests

LVD, ESPE, and Functional Safety Tests

Safety verification process in accordance with ISO 13849-1 & IEC 61496

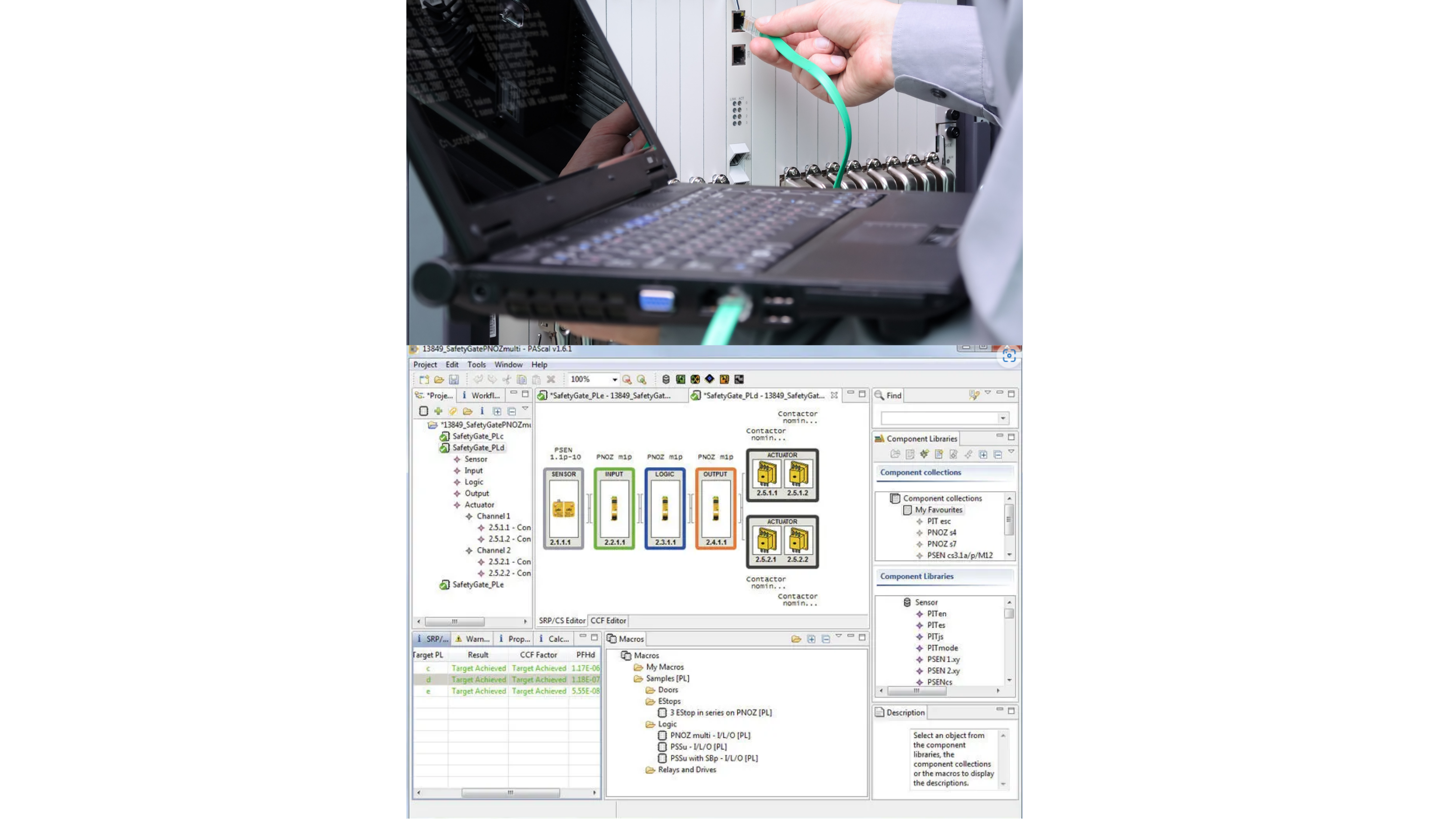

Preparation of machine safety compliance reports (e.g., PAScal Safety Calculator)

Machine Safety: Performance Level (PL) and Safety Integrity Level (SIL) tests

LVT Test

High voltage (hipot) test – Measures the strength of electrical insulation.

Insulation resistance test – Checks the quality of the insulation materials inside the device.

Leakage current test – Tests for unwanted current leakage to the body of the electrical device.

Earth continuity test – Checks the reliability of the device's grounding connection.

Functional tests – Determines whether the device operates correctly at its nominal voltage and current values.

All tests are conducted with our own equipment and in-house.

PAScal Safety Calculator

Performance Level (PL) calculation

Determines PL (a, b, c, d, e) levels according to the EN ISO 13849-1 standard.

Calculates the failure rates (MTTFd), diagnostic coverage (DC), and structure categories of the components in the safety circuit.

Safety Integrity Level (SIL) analysis

Verifies SIL 1, 2, or 3 levels according to the IEC 62061 standard.

Performs reliability calculations for safety functions.

Failure Probability Calculations (PFHd)

Determines the system's risk level by calculating the dangerous failure rate (PFHd).

Determining Category and Diagnostic Coverage

Evaluates safety levels such as Category 1, 2, 3, or 4.

Examines the diagnostic coverage of sensors, logic circuits (PLC, relays), and actuators.

Documentation and Reporting

Generates automatic validation reports for the analyzed safety functions.

Reports are used in CE certification processes and risk assessments.

All tests are conducted with our own equipment and in-house.

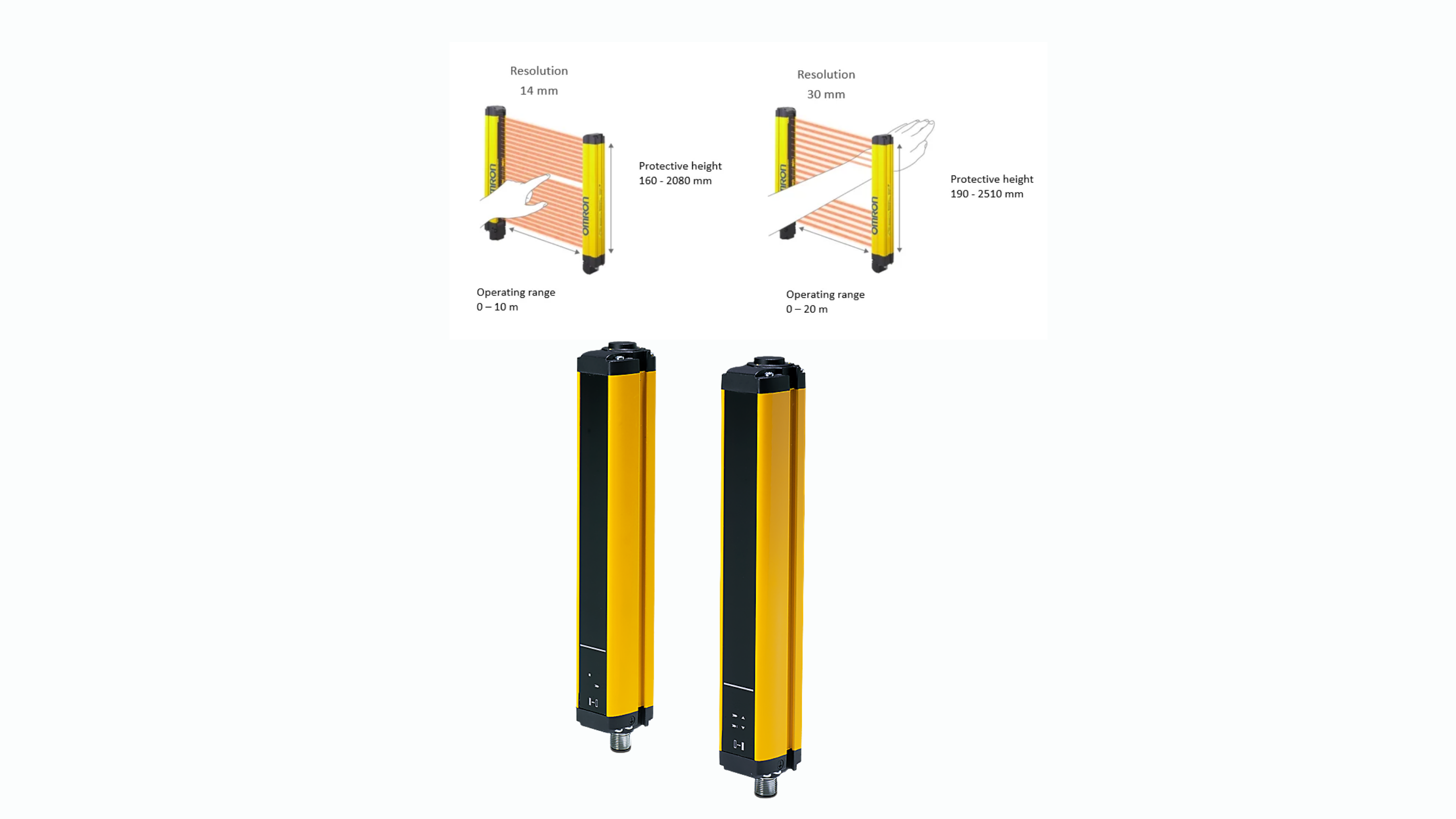

ESPE (Electro-Sensitive Protective Equipment)

Detection distance and sensitivity test

Performed to verify that the light curtain or sensor operates at the correct distance and sensitivity.

Tests whether the sensors work correctly with the minimum detection object (test rod).

Response time test

The safety sensor's time to stop the hazardous movement is measured.

This time is evaluated along with the total stopping time of the machine.

Positioning and dead zone test

It is checked whether the sensors or light curtains operate without leaving a dead zone (blind spot).

It is ensured that the hazardous area is fully protected.

Safety relay and PLC integration test

It is tested whether the ESPE system operates compatibly with the safety relay or safety PLC.

It is checked whether the sensor signals are processed correctly and can stop the machine.

Electrical connection and power tests

It is measured whether the ESPE is correctly connected to the power supply and operates stably.

It is tested whether there are any incorrect connections or voltage drops.

All tests are conducted with our own equipment and in-house.